Fully integrated functionalities

Nomenclature

Evaluation by criteria

Criteria are defined, standardized and balanced according to product category.

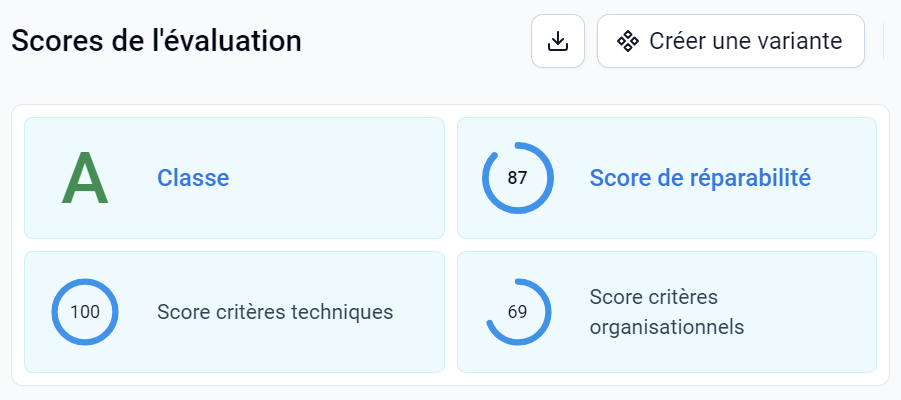

Detailed score

Receive your repairability class and associated score, clear and precise.

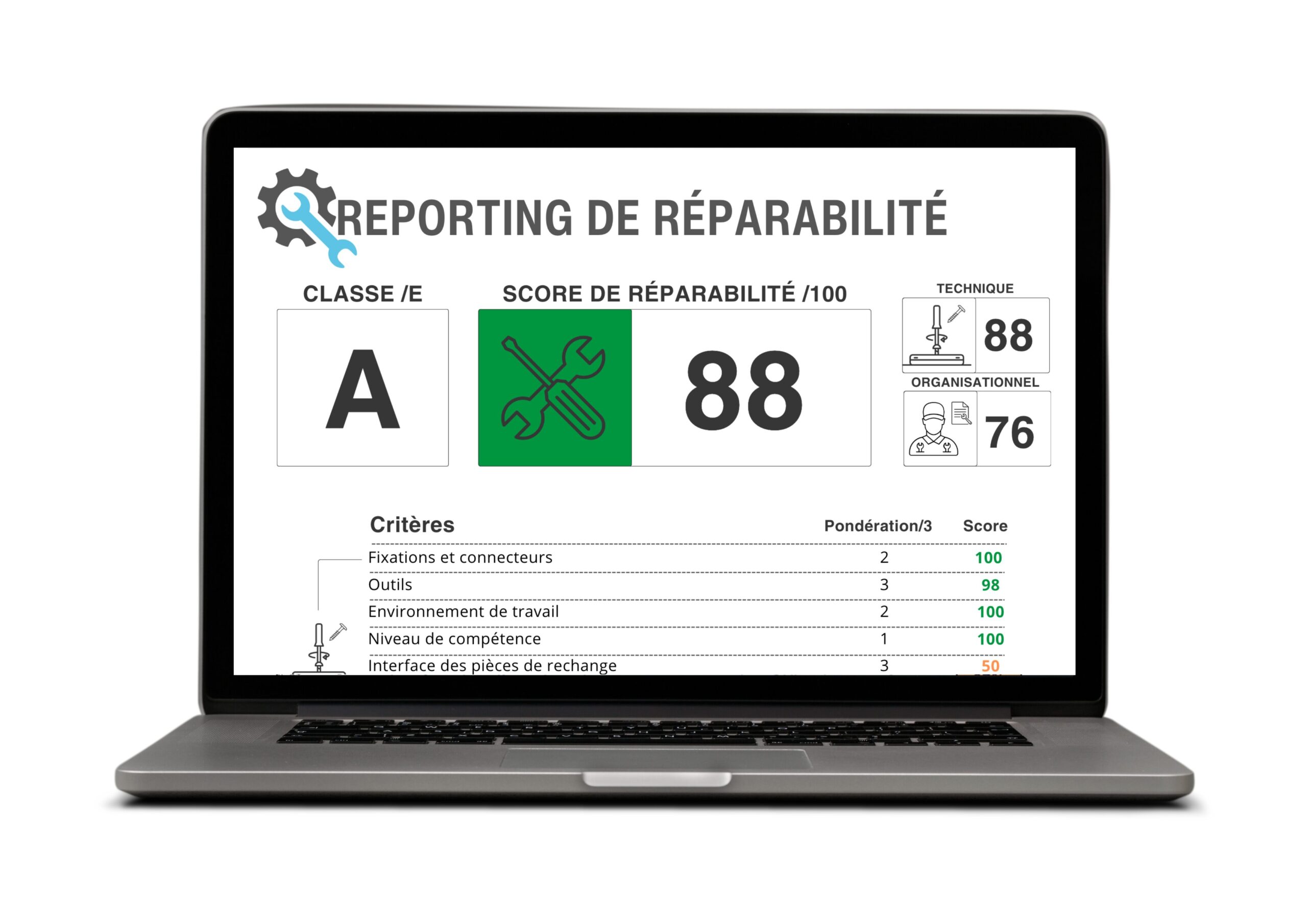

Detailed report

Receive a full report with in-depth sub-scores and suggestions for improvement.

Alternative scenarios

Verification

Adapted for everyone

All products

All companies

At all stages

Collaboration & security

The subscription gives you access to a company account that you can organize as you wish, managing access for your internal and external collaborators on each evaluation project.

The security of your data is our top priority. We use advanced encryption systems to ensure the confidentiality of your information. Additionally, RepairAbility is equipped with an SSO authentication system.

Variations for simulation

Drive improvements

Guidelines and examples

PDF report export

To facilitate communication internally or with your stakeholders, a PDF report can be generated. It summarizes all the calculation processes, product details, scores, and recommendations for each criterion and part.

The report includes the following elements:

- Repairability score and class

- Organizational score and technical score

- Detailed results for each criterion and part

- Interpretation of the results

- Simulation of score improvements